Медицинские клиники с современным оборудованием могут значительно повысить качество диагностики и лечения. В Москве множество клиник, которые инвестируют в передовые технологии для обеспечения высокого уровня

Алкоголизм — это серьёзная проблема, с которой сталкиваются многие семьи в России и, в частности, в городе Пермь. В борьбе с этим заболеванием важную роль

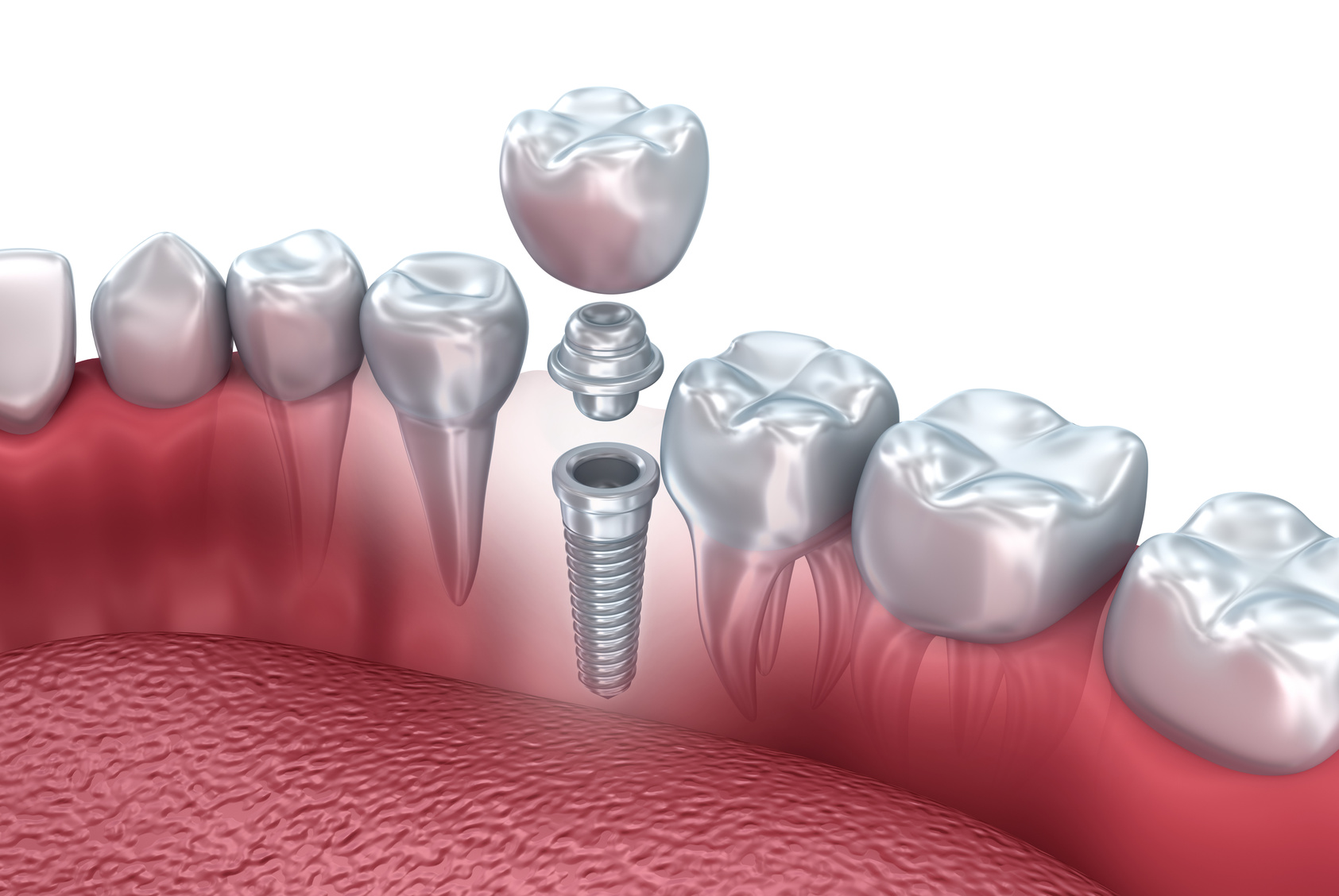

Имплантация зубов – это передовой метод восстановления потерянных зубов, который позволяет не только восстановить функциональность зубного ряда, но и сохранить естественную красоту улыбки. В Иркутске

Москва как большой мегаполис предлагает множество медицинских услуг, включая лабораторные исследования. Среди них большое значение имеет анализ на пролактин, ключевой гормон, влияющий на множество процессов

Столица России не только политический и экономический центр страны, но и место, где сосредоточены ведущие медицинские учреждения, в том числе и в области стоматологии. Стоматологические

Зачем нужно промывать миндалины? Промывание миндалин — это процедура, которая помогает очистить миндалины от слизи, бактерий и других загрязнений. Это особенно важно для людей, страдающих

В современном мире, где цифровые технологии занимают всё большее место в жизни человека, интернет-шопинг становится неотъемлемой частью нашего быта. При этом каждый потребитель стремится не

Урология — это раздел медицины, который специализируется на диагностике, лечении и предотвращении заболеваний мочеполовой системы у мужчин и женщин, а также на репродуктивной системе мужчин.

В мире, где экология занимает всё более важное место в жизни каждого человека, внимание к экологически чистым продуктам растёт с каждым днём. GreenWay, международная торговая

В настоящее время, заболевания печени становятся все более распространенными и серьезными проблемами здоровья. Фиброз печени — одно из наиболее серьезных печеночных заболеваний, которое требует внимательного